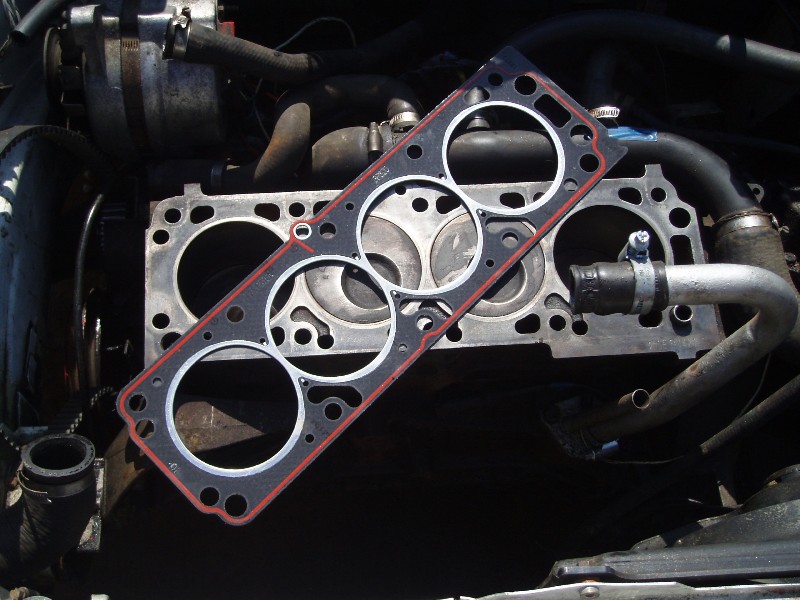

One of the things for which mainly gaskets are used is for various kinds of sealing applications which takes place from residential use to industrial use. Gaskets mainly prevent leaking and at connection point it stops the loss of pressure where other solid materials or strong materials come together, like two metal pipes. Since gaskets are common and pivotal in several processes, they are manufactured in different varieties which comprises of silicone rubber too. Synthetic rubber, silicone is made by mixing silicon with oxygen, hydrogen, and carbon and other additives. Other additives are included in some of the cases. The pivotal chemical difference between silicone and other kinds of polymers is that it comprises of a Si-O-Si backbone, rather than a carbon backbone.

Resistance Power –

You can also get agricultural gaskets India. Just follow the link mentioned here. One of the biggest benefits of silicone rubber is that it has resistance power to acids, chemicals, bases, water, solvents, oils and some extreme temperatures. Not like natural rubber, silicone is also resistant or has the resistant power to ozone cracking and UV rays, both of which makes the silicone gaskets more trustworthy options/material for sustained use outdoors. Light industrial applications and consumer products make up the mainstream of the market share for silicone. You must have seen silicone gaskets in swim goggles, temporary food storage containers, baking material sealants and various other consumer applications.

Stopping Leakages –

There are also available in the market industrial gaskets India for its various uses in the industries. Silicone gaskets are also has use in medical devices like that of incubators, dialysis machines, infusion pumps. The capabilities and life of the silicone rubber gaskets make them a top-notch choice for the consumer manufacturing and industrial products too. Gaskets also prevents leakages too. One of the biggest benefits of using a gasket is to stop the leakages from happening. Between the interjoining surfaces you can stop the leakages through the proper use of gaskets. A gaskets work is to fill up the gap between the 2 different facets. To lessen the unwanted friction, it connects the machine components together. Besides that, gaskets also stop wear down of the machines making sure that they are used safely.

Prevention of Corrosion –

There are FDA approved gaskets for food and pharma industry that helps in avoiding corrosion. Products which are like pipe flanges they are prone to getting corroded. If you do not apply or use the gasket to connect the flanges, then the joints will corrode and break. Many of the gaskets different types prevent corrosion which comprises of spiral wound gaskets too. Gaskets are the one that can withstand high temperature. Gaskets are used in several different industries which comprises of petrochemical, pharmaceuticals, water and gas. These industries depend on the components that are chemical resistant. Besides that, which can withstand high temperature. For instance, gaskets that can handle high temperature can withstand the temperature up to 1000°C. There are also eco-friendly gaskets that are available like that of HT gaskets.

Gaskets for Safety –

You can look online for spiral wound gasket manufacturers India. Check the link mentioned here. One of the most important functions is that gaskets provide safety functions. It can be responsive to any kind of pressure build up. If this function is not there then you can have a pipe burst. Therefore, it is important to select the correct gasket for the right machinery. You can ask that to your gasket supplier.