The generator used for heavy machinery may affect the operating efficiency, equipment durability, and successful completion of a project. In high-power applications, 3-phase generators are quite excellent. Their durability, voltage uniformity, and ability to carry enormous loads that do not change make them a must for construction, industry, and mining. This article discusses the hardware requirements that make 3-phase generators vital for heavy equipment power.

Strong Construction for Durability

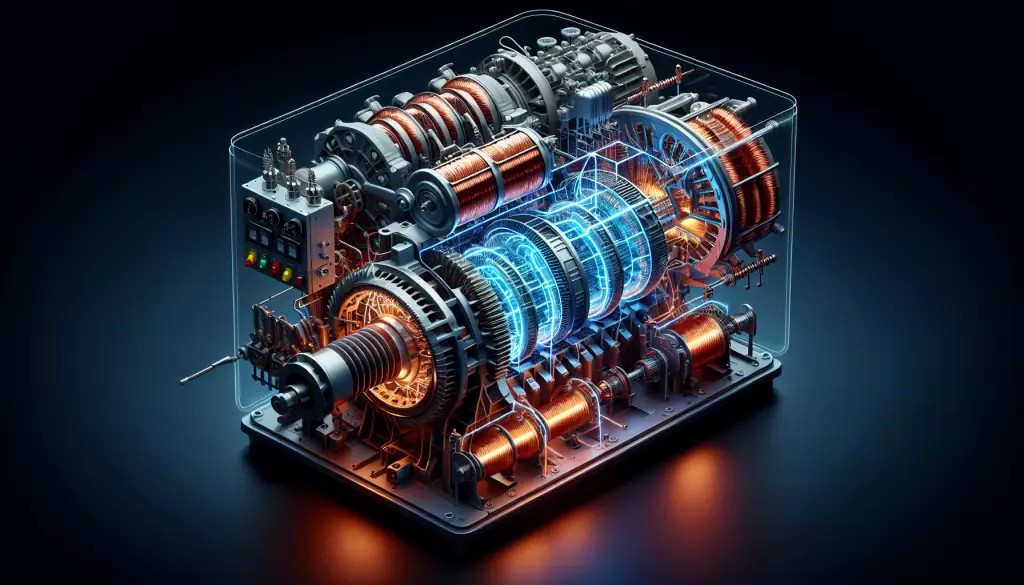

3-phase generator parts are robust. They use industrial alternators to resist continuous mechanical and thermal stress. A generator with heavy-duty bearings, strengthened engines, and improved cooling systems runs for extended periods without overheating. This strong structure reduces the cost of maintenance and boosts operating lifetimes, hence suitable for heavy equipment power.

Voltage Stability for Reliability

The most important advantage that makes 3-phase generators stands out is the smooth and steady voltage. Here, in a 3-phase system, three such alternating currents with different sets of offsets of 120 degrees are produced. Whereas the fluctuation in a single-phase system affects heavy equipment performance, this produces smoother and steadier output. Heavy equipment needs consistent voltage. Hydraulic systems, large compressors and electricity-driven motors require stable electricity to function. Fluctuations in voltage may result in early wear of the equipment, increased downtime and higher frequency of maintenance. The 3 phase generator has stable voltage which protects sensitive equipment, enhancing the effectiveness that makes operations efficient.

Continuous Loads Ability for Large Appliances

Heavy equipment machinery requires a large amount of electricity. Where 3-phase generators will come in handy is where huge continuous loads are expected. For example, where high power needs are being met and do not need refueling, three-phase generators do the trick compared to standard generators. They have their three-phase output that has boosted their general power rating, making it suitable for demanding applications.

Effective Power Distribution

The other important aspect of 3-phase generators is power distribution efficiency. In a 3-phase generator, electricity is spread over three wires instead of one. This significantly reduces line current. Thus, the reduced wire resistance energy loss will improve the system’s efficiency. Meaning heavy machinery will run for longer without fuel expenses.

Besides, 3-phase generators distribute power loads. This makes the system more efficient. Generators prevent wire overload since they distribute electrical current over three phases evenly, thus increasing the lifetime of the generator and powered equipment. As such, businesses can, therefore, improve their activities while wasting the least energy and costs.

Easy Maintenance and Use

While three-phase generators are more manageable and easier to operate than single phase, problems can quickly be picked up and corrected when a good generator is maintained. Many 3-phase generators are modular, offering easy access and replacement without downtime even in high demand applications.

3-Phase Generators Are Essential

On a whole, 3-phase generators are very important to power huge equipment in such various industries. They can endure harsh conditions and sustain constancy of voltage well to protect expensive apparatuses. They could well cope with heavy loads of continuous flow in a massive scale, making them perfect for high power applications.